Industrial AI

Industrial AI represents a confluence of Domain and Data, connected through Discipline, focusing on Industry-inspired Research, Methodological Innovation and Education, and Fundamental Research with Systematic Thinking. By integrating these key aspects, Industrial AI facilitates a more coherent understanding and application of AI technologies in the industrial sector. This cohesive approach enables businesses to address complex challenges with innovative solutions, leveraging the synergy between domain knowledge, quality data, and disciplined methodologies. Through methodological innovation and fostering education, along with a commitment to fundamental research and systematic thinking, Industrial AI propels the field toward new heights, aligning the theoretical frameworks with practical industrial needs.

COMMON ISSUES IN INDUSTRIAL SYSTEMS

Many data in the industry currently suffer from issues related to either Usefulness or Usability, leading to complications in extracting valuable insights. Addressing and resolving these data quality problems is essential, as it paves the way for more effective utilization of data, transforming it into actionable information that can drive decision-making and foster growth.

DATA-CENTRIC APPROACH

A Data-Centric Approach focuses on considering the quantity and quality of data, ensuring that the right methods are selected for problem-solving. By prioritizing the integrity and relevance of the information, it enables more precise analysis and decision-making tailored to specific challenges.

APPLICATIONS

With a dedication to excellence in several key areas, Industrial AI identifies the unique intricacies of each domain and utilizes specialized knowledge and data to craft solutions tailored to specific needs, offering unparalleled precision and efficiency for a wide array of industrial applications.

PLATFORM INDEPENDENCE

The Center’s tools can be reconfigured for use on many platforms or software languages. Currently, the Center focuses on commercially available engineering platforms and cloud-based platforms.

AI Factory and Data Foundry Platform for Next-Generation Industrial GAI

Our research in AI Factory and Data Foundry will define a practical version of GAI tailored to industrial applications:

Cross-domain adaptability: One model can handle tasks in predictive maintenance, quality control, logistics, etc.

Reasoning and planning: Able to make decisions or suggest strategies.

Perception-action loop: Understand data and act upon it.

Learning from minimal supervision or data.

Common types of industrial datasets:

Sensor data (time-series): From IoT devices, PLCs, etc.

Visual data: Images/videos from inspection systems, cameras.

Tabular data: Logs, ERP, MES systems.

Control data: Commands and feedback loops in automation.

Event logs: Maintenance records, failure reports.

Each of these can be used to train systems for perception, prediction, control, and planning.

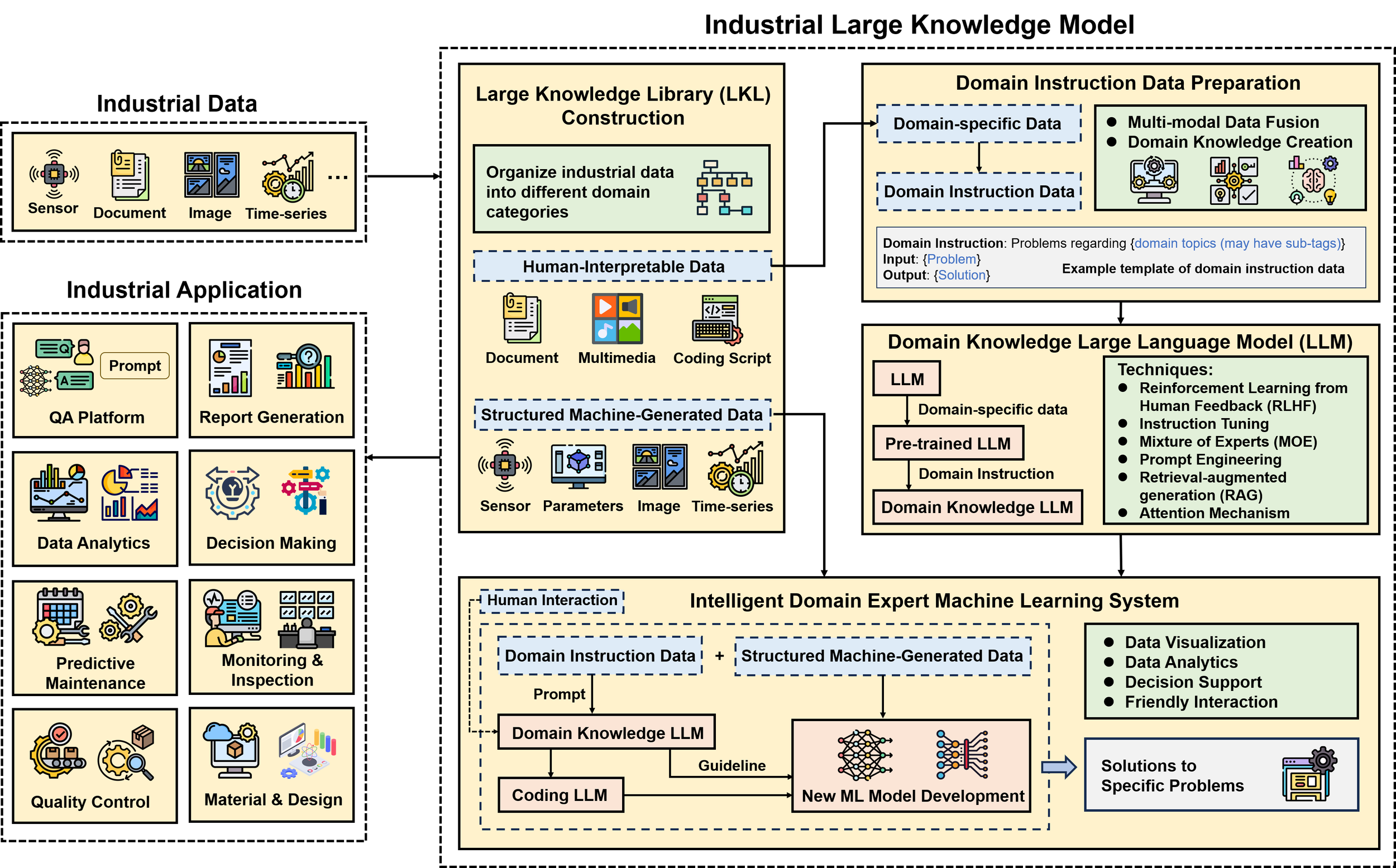

Industrial Large Knowledge Model (ILKM) Building Blocks using LLMs

We will build general industriall foundation models for industrial AI, designed to unify data, models, and knowledge into a scalable framework.

1. Retrieval-Augmented Generation (RAG) Integration

Retrieve relevant technical manuals, reports, standards, sensor logs, or prior cases from a knowledge library.

Combine retrieved context with the model’s generative reasoning to answer complex queries.

2. Fine-Tuning and Adaptation

Task-oriented fine-tuning: e.g., remaining useful life (RUL) prediction, anomaly diagnosis, etc.

Instruction tuning: aligning responses to the style and requirements of industrial operators.

Reinforcement learning with human or expert feedback: ensuring safe and practical recommendations.

3. Agentic AI System Development

Enable perception, reasoning, planning, and action loops.

Provide structured knowledge to guide decision-making.

Interfacing with external tools, digital twins, or control systems for action execution.

GAI Building Blocks Without LLMs

We will build general intelligence-like systems using modular, hybrid, or neuro-symbolic approaches, combining multiple AI/ML techniques.

1. Neuro-Symbolic Systems

Combine neural networks for perception with symbolic AI for reasoning.

Example: Use CNNs or transformers (non-LLMs) for image/sensor data, then a rules engine or logic program for decision-making.

2. Reinforcement Learning (RL)

Ideal for industrial control, robotics, optimization.

Can be trained to generalize across multiple environments or machines.

Example: Use RL for quality and performance, and energy optimization in different production lines.

3. Multi-modal Integration

Build systems that combine vision, time series, and control data into a unified representation.

4. Transfer Learning and Domain Adaptation

GAI needs models that can learn how to learn:

Use meta-learning to train on a wide variety of industrial tasks and enable quick adaptation to new tasks with little data.

5. Continual Learning Systems -Stream-of-X (SoX) Machine learning

To mimic general intelligence:

Build models that learn continuously without catastrophic forgetting.